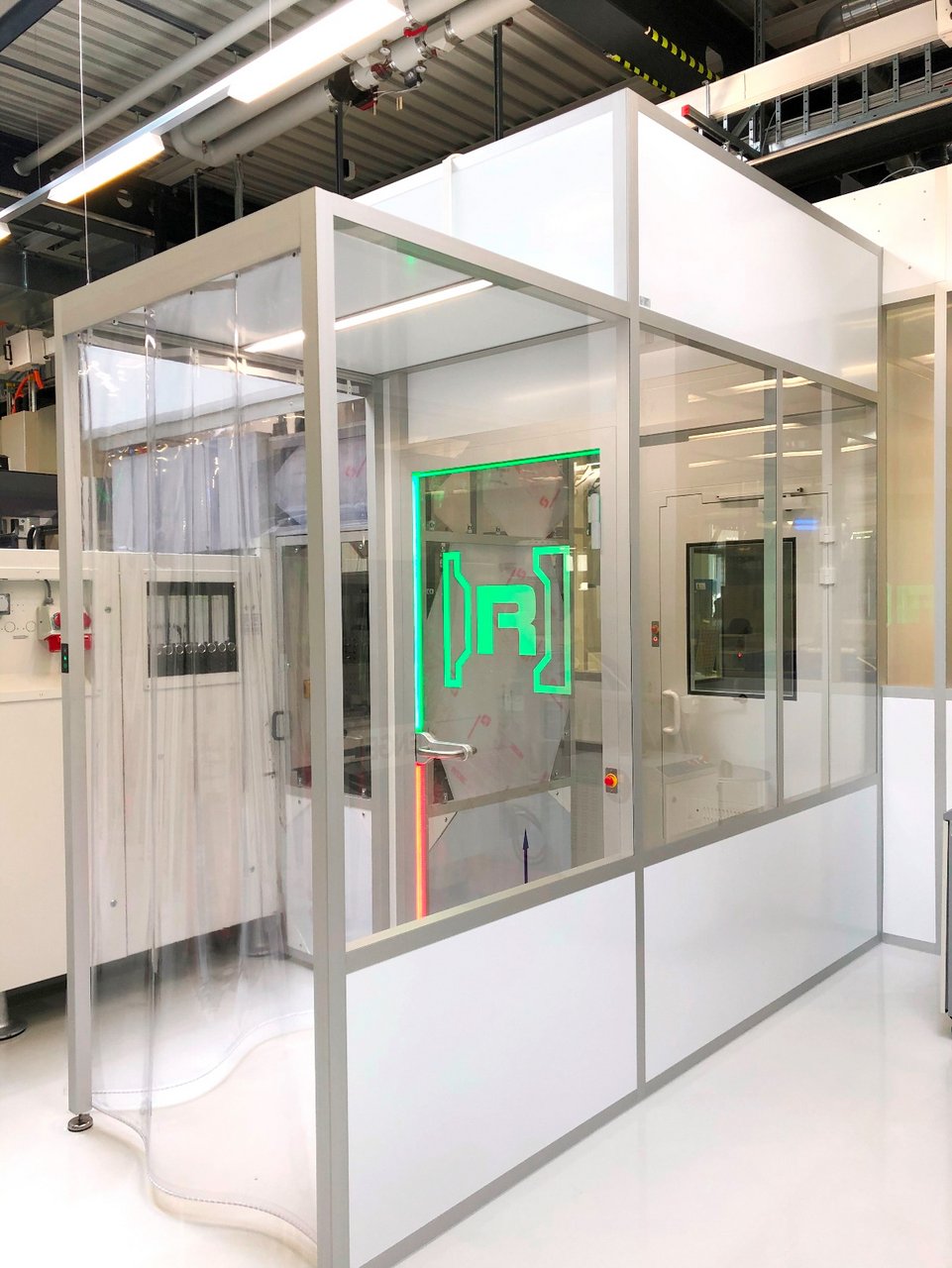

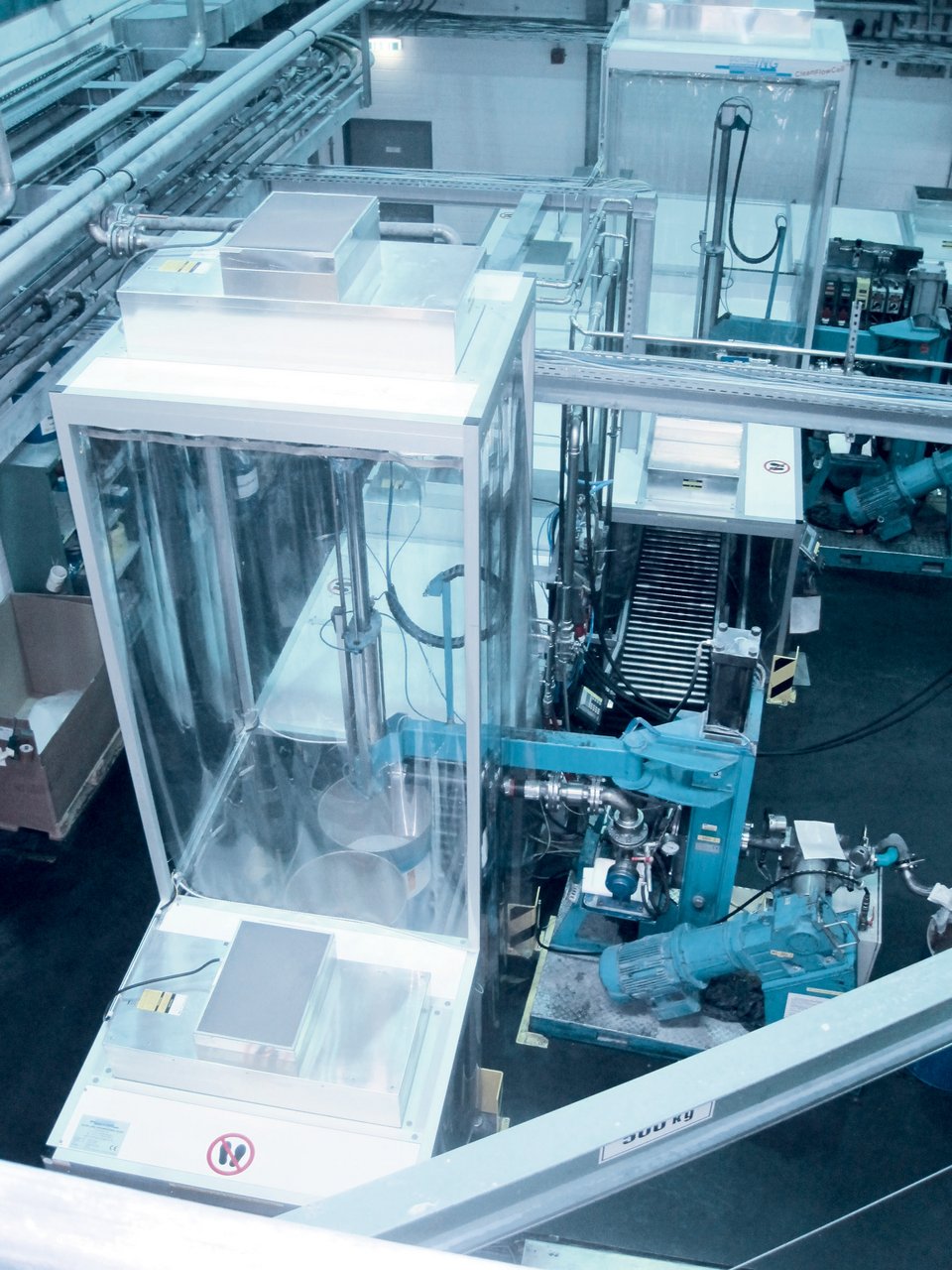

The requirements for manufacturing products with ever smaller dimensions, more precise shapes and excellent surfaces are very high. You can achieve a safe manufacturing process with the customised machine housings from Schilling Engineering. The cleanroom enclosure is made with PVC film curtains and is flexibly adapted to the size of the machines and conveyor systems. Filter systems with directed air flows (laminar flow) displace unclean air from the process in your cleanroom.

We will create an individual machine housing for you that meets the standard specifications of a cleanroom environment. Please send us a non-binding enquiry or contact us by phone or e-mail for individual advice. Our experts will help you.

Safe production with machine housings

You can meet the increasing demands of the manufacturing process with customised machine housings from Schilling Engineering. They are particularly effective in confined spaces where cleanroom conditions must be met, but space is at a premium.

The enclosure is made with PVC film curtains and is flexibly adapted to the size of the machines and conveyor systems. Filter systems with directed air flows displace unclean air from the process

Machine housing with laminar flow

For the production of sensitive products, a controlled environment for the manufacturing process is absolutely essential. The so-called low-turbulence displacement flow, also known as laminar flow, makes a significant contribution to this. This is achieved via the filter fan units integrated in the machine housing. Harmful particles are captured by an artificially generated, parallel air flow and carried out of the room.

Our machine housings protect your process plant from particles from the production environment by creating a controlled laminar flow. The targeted airflow reduces the particle concentration to a minimum and prevents the contamination of sensitive products.