A match ball for the derby

Last Friday saw the football derby between VfB Waldshut and FC Tiengen, with SCHILLING ENGINEERING sponsoring the match ball.

Read more

Sponsoring animal shelter service

We love animals 🐾💚. We just don't let them into our cleanrooms. Not a single one. We're strict about that.

Read more

Donation to the Förderverein Jugendhilfe Kinderheim Alpenblick e.V.

The staff at Alpenblick Children's Home are dedicated to the welfare of the youngest members of our society. The children's home provides care, education and support for children and young people who,…

Read more

Donation to Bergwacht Schwarzwald e.V.

Feldberg is home to the most important mountain rescue centre in Baden-Württemberg. Up to 500 mountain rescue operations are carried out from here each year, providing fast and unbureaucratic…

Read more

Welcome to the team!

We are delighted to welcome two new apprentices to Schilling Engineering.

Read more

Schilling Engineering GmbH with excellent employer appeal

Constance/ Wutöschingen - Schilling Engineering GmbH is one of the best employers in Germany. The specialist for cleanroom technology was awarded by the Center for Employer Attractiveness (zeag GmbH)…

Read more

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/1/c/csm_25Jahre_Mitarbeiterfest_1__9__125316df3e.jpg)

Company anniversary and handover

Günther Schilling retires after 25 years and hands over the reins of the cleanroom company to his daughters.

Read more

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/2/7/csm_20230615_Kundenevent_06.jpeg_e426ac5ac8.jpg)

25 years Schilling Engineering GmbH

In-house trade fair, training courses, staff party, open day

Read more

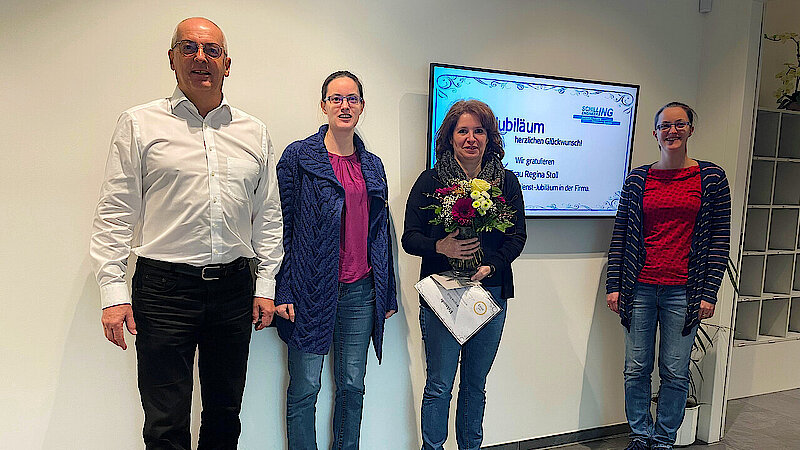

10 years of service - Many thanks to Regina Stoll

Regina Stoll has already been part of Schilling Engineering GmbH for ten years.

Read more

![[Translate to English:]](/fileadmin/_processed_/6/3/csm_17_Ziele_UN_f3fec356ea.jpg)

17 UN Sustainable Development Goals - what can we contribute?

Taking responsibility. As a medium-sized family business, we have also thought about this topic.

Read more

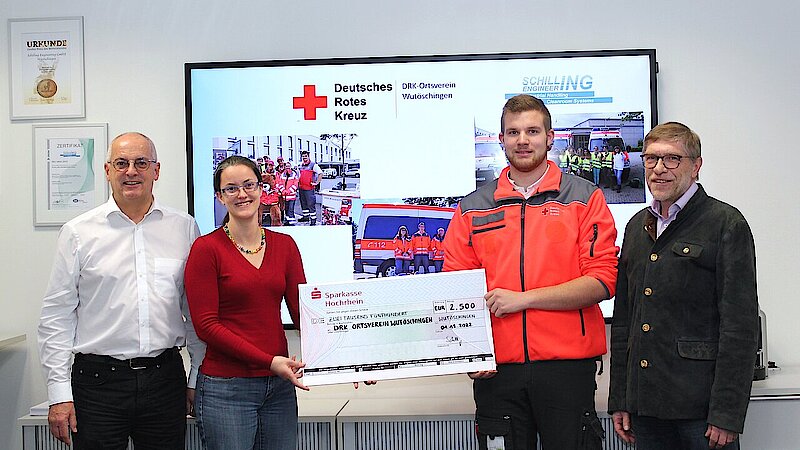

Donation to the DRK - Local Association Wutöschingen

Supporting the important work of the German Red Cross is a matter close to our hearts. With tireless commitment, the local association Wutöschingen takes care of the health of all of us - a big thank…

Read more

Donation to the Support Association Special Olympics Hochrhein e.V.

We were delighted to welcome a whole delegation from the "Förderverein Special Olympics Hochrhein e.V." at the beginning of December. The association supports athletes with various handicaps who train…

Read more

Badge of Honour Award "Grand Prix of SME 2022"

Die Oskar-Patzelt-Stiftung hat Schilling Engineering aus 4.546 nominierten Unternehmen unter die Top 15 gewählt und mit der Ehrenplakette 2022 ausgezeichnet.

Read more

Welcome on Board

A warm welcome and good luck to our new apprentices, Jannik, Bastian, Justin and Jasmin!

Read more

Technology Day: Cleanroom and Injection Moulding

We were able to experience a very special event on September 8. Together with the Swiss company Stamm AG, we invited customers and interested parties to a joint technology day on the subject of…

Read more